Selection and use of filters

Any device capable of processing a signal can be called a filter. In modern communication equipment and various control systems, filters are widely used.

Among all electronic components, filters are widely used and the technology is relatively complex. The quality of the filter directly determines the quality of the product, so the research and production of the filter have always been paid attention to by various countries.

1. How to choose a power line interference filter?

Some customers think that the higher the insertion loss of the EMI filter, the better, and the more filter network stages, the better. Actually this is not the right way to choose a filter. In addition, the more filter stages, the more expensive the price, the larger the volume and weight. In fact, the way to select and evaluate a power line filter is to install it on the equipment and test it. As with the filters above, performance is highly dependent on the load impedance of the device. It cannot be derived from impedance (50ω) insertion loss data alone.

It is a complex function of filter element impedance and device impedance, whose magnitude and phase vary over frequency. Conducted emission control (FCC, VDE) and sensitivity control required for filter selection tests at different performance levels on equipment.

2. Do all filter networks have the same circuit and component values?

All filter networks with the same circuit and component values have different performance. Component values are specified and measured at a certain frequency (usually 1KHz), and filter performance is required over the entire frequency range, not just the frequency at which the component is measured.

The structure of the components and the method of inserting the filter are very important to the performance of the filter.

3. Is installation important to filter performance?

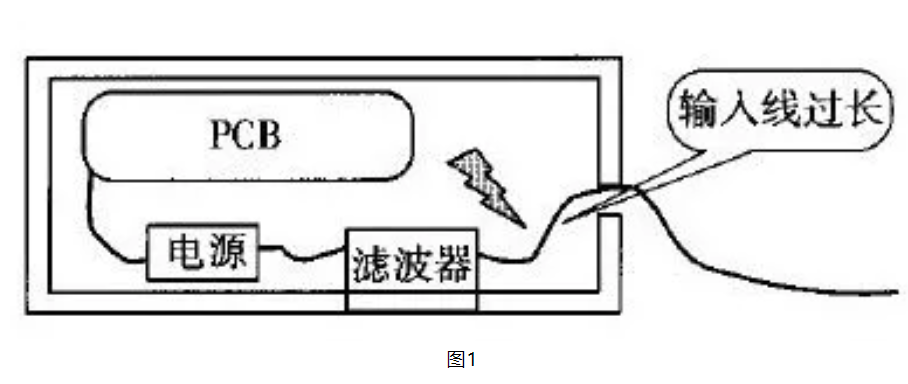

Installation and wiring have a great influence on the performance analysis of the filter. Power line filters are installed as far as possible at the power line input of a device.

Filters are barriers to high-frequency data signals, and their role must not be overridden by discrete capacitively coupled system power input lines and power output lines or any other conductors of the protected equipment.

When installing the power filter, pay attention to the following:

1) There should be a good electrical connection between the housing of the power filter and the device. Do not install filters on insulating boards or painted surfaces. Mount it on the metal case. Avoid using long ground wires as this greatly increases ground inductance and resistance, from

And seriously reduce the common mode rejection performance of the filter. A better method is to use metal screws and spring washers to securely fasten the filter's metal shield to the chassis at the system power inlet, or use copper braided ground straps to connect to the site.

2) When bundling equipment cables, it is forbidden to bundle the input and output cables of the filter together. This exacerbates the electromagnetic coupling between the filter input and output, seriously destroying the filter's ability to suppress EMI signals.

3) Do not install the filter inside the equipment shield. Because of this, the EMI signals on the internal control circuits and components of the equipment will be directly coupled to the outside of the equipment due to the radiation generated on the terminal leads of the filter, causing the equipment shielding to lose its effectiveness.

Suppression of EMI radiation generated between internal management circuits and components.

4) It is recommended to use the original shielding of the equipment to effectively isolate the input and output of the filter, and control the possible electromagnetic coupling between its input and output to a lower limit.

Previous :

Related products